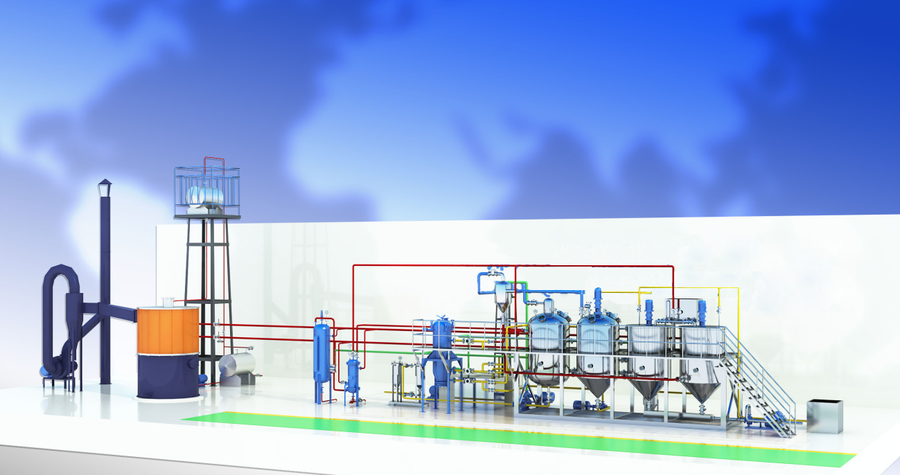

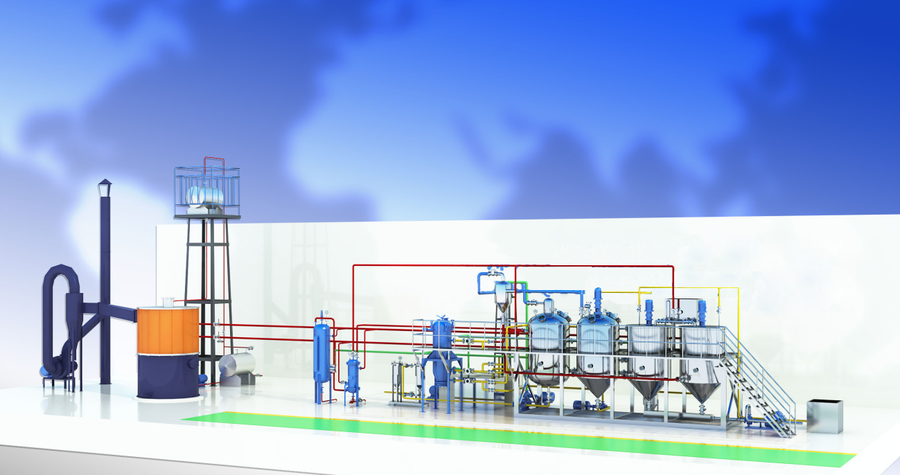

Number 1:Pre-press workshop

I.Process Description

General introduction

Oil seed from the silo by scraper and hoist conveyor into the pre-press workshop, then go to the vibrate cleaning sieve to remove the impurities, and then into the destone machine, remove the similar size of stone impurity from the material.After the destoner go into the magnetic separator to remove ferromagnetic impurities, and then be conveyed into the crusher, the crusher will break the castor,then sent by the conveyor to the rolling mill, the rolling mill will roll oil seed into thin slices, in order to facilitate the next steaming process, oil seed in the steaming process, through the heating, adjust the material temperature and moisture, so that the material is suitable for pressing, then go to the pre-pressing process.The material go to the screw press machine,worked by the worm and the cage,the pressure is higher,and press the oil out from the material.The crude oil which with slag will go to the clarifying tank,after sedimentation and slag remove,the oil will be pumped to the leaf filter,then get the crude oil go to crude oil temporary storage tank,then go to refining workshop.And the slag will go to press machine to press again,while the cake go to solvent extraction workshop.

II.Main process description

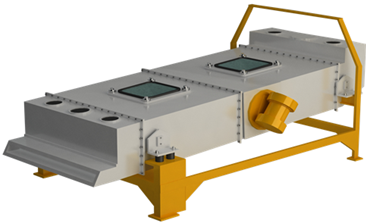

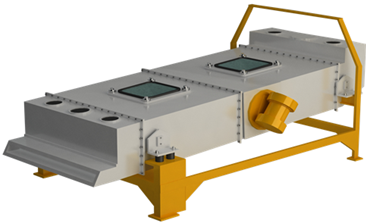

1.Cleaning: In order to obtain high effective cleaning, ensure good work condition and production stability, high efficient vibration screen was used in the process to separate big and small impurity.

Vibrate Cleaning Sieve

2.Magnetic selector:Magnetic separation equipment without power and exhaust system were used to remove iron. Dust removing wind net is installed.

Magnetic separator

3.De-stonner :Suction type gravity stoner removing machine was applied to remove the shoulder stone and earth.

De-stonner

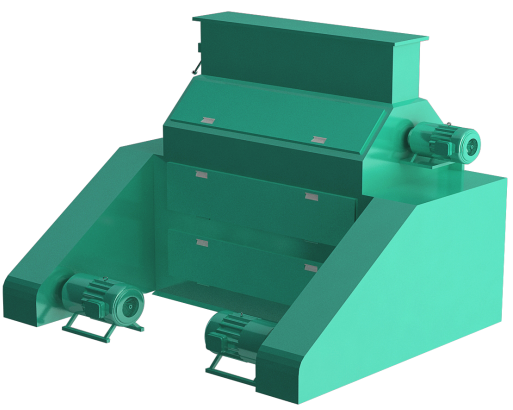

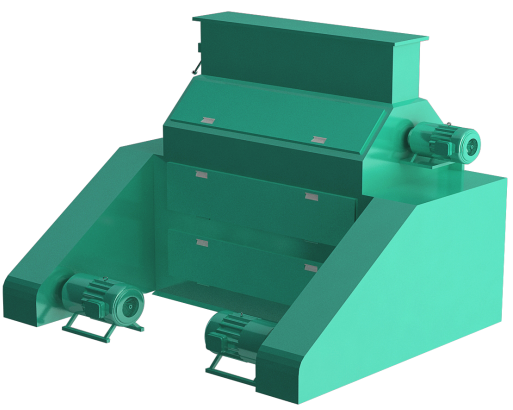

4.Crusher:Crusher means to crack the oil seed into small pieces,easy for flake and the followed solvent extraction process.

Crusher

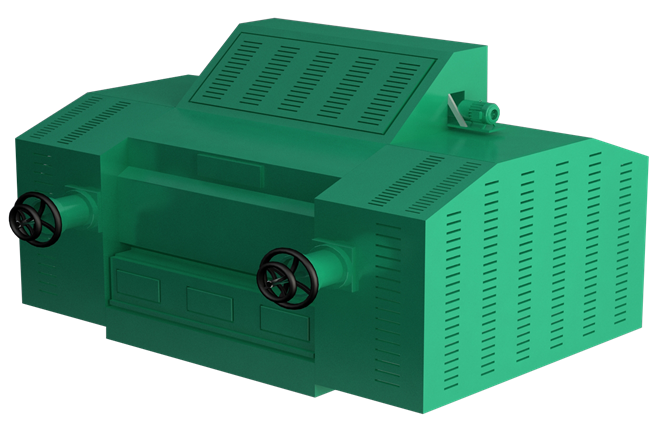

5.Flaker: Flaking means a certainty granularity of oil seed was prepared for flaked of about 0.5 mm, the oil of raw material can be extracted in the shortest time and maximum.

6.Steam Cooker:This process is heating and cooking for canola seed which is easy to separate of oil and can provide the oil quantity from prepress machine. It is easy to operate and have long life.

Steam Cooker

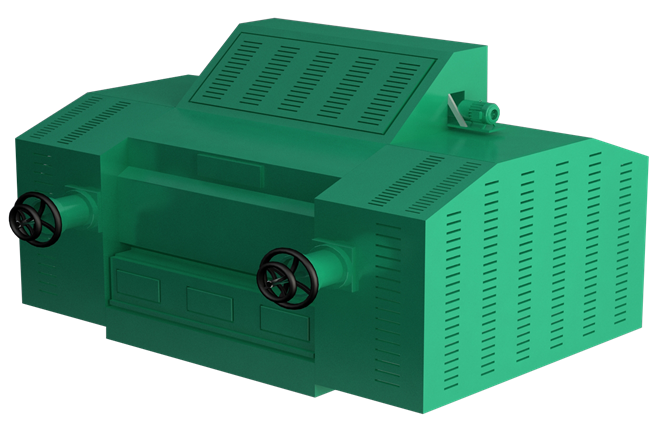

8.Pre-pressing machine:Pre-press machine is continuous screw press machine which is suitable to the plant oil materials which has high oil content. The instruction of the cake is loose and easy to make the solvent permeate, the oil content of cake and moisture used for solvent extraction.

Pre-pressing machine

III.Advantage of the pre-treatment process

1

Cleaning section remove the impurity from oil seed,make sure no impurity cause demage of the machine,machine have long life.

2

Soften,crushing and flake section open oil cell,make it easy to get oil out.

3

Make seeds in the best condition, so as to extract oil out of oil seeds sufficiently and easily in the solvent extraction section. In other words, it is applied to improve the production efficiency and save energy and costs maximum.

IV. Equipment List:

20 TPD Cottonseed and sunflower oil Pre-pressing Equipment list |

序号number | 位号

Position Number | 名称

Name | 型号

Model | 数量

Q.T.Y | 动力Power

(KW) | 单项总动力

Total Power(KW) | 备注

Remarks |

1 | L101abcdef | 斗提机

Bucket elevator | DTG26/13 | 6 | 0.75 | 4.5 | Strong belt, plastic winnowing pan |

2 | C201 | 清理筛

Cleaning sieve | TQM80 | 1 | 0.5 | 0.5 | 去除大杂、小杂

Clean big and small impurity |

3 | G201 | 永磁筒

Magnetic separator | TCXT20 | 1 | 0 | 0 | 去除铁杂

Remove iron impurity |

4 | C202 | 去石机

Destoner | TQSF45 | 1 | 0.5 | 0.5 | 去除并肩石

Remove the stone |

5 | T101 | 齿辊破碎机

Tooth roll crusher | PSG25*600 | 1 | 5.5 | 5.5 | 双对辊破碎

Roller crusher |

6 | G204 | 壳仁分离筛

Kernel and husk separate screen | TFLS100*200 | 1 | 0 | 0 | 分离壳仁

Separate the kernel and husk |

7 | G203 | 液压轧胚机

Flaker | YYPT2*40 * 80 | 1 | 22.25 | 22.25 | 1550×1300×1370, 约3.2t |

8 | E202 | 四层蒸炒锅

Cooker | YZCL150*4 | 1 | 15 | 15 | 碳钢,导热油加热

Carbon steel,conduction oil heating |

9 | L214 | 分料绞龙

screw conveyor | LSS16 | 1 | 1.1 | 1.1 | 碳钢

Carbon steel |

10 | Z101ab | 压榨机

Pre-press machine | 200型 | 2 | 37 | 74 | 带3层炒锅;

With 3 layers cooker, one for using, |

11 | L215 | 油渣刮板

Oil residue scraper | YZGB16 | 1 | 1.1 | 1.1 | 碳钢

Carbon steel |

12 | L212 | 饼绞龙

Cake screw conveyor | LSS16 | 1 | 1.1 | 1.1 | 碳钢

Carbon steel |

13 | L219 | 刮板

Cake scraper | TGSS16 | 1 | 2 | 2 | / |

14 | V205 | 澄油箱

oil tank | CYX3.2 | 1 | 1.5 | 1.5 | 链条传动,带过滤筛板,捞出沉淀的油渣碳钢

Carton steel, chain driving, with filter blade, dredge up settleed oil residue |

15 | P201 | 过滤油泵

oil filter pump | 40-160 | 1 | 3 | 3 | 碳钢

Carbon steel |

16 | F205 | 叶片过滤机

Leaf filter | NYB4 | 1 | 0 | 0 | 不锈钢滤板,过滤能力:0.5-1.2t/h

Stainless steel filter plate;filter capacity 0.5-1.2t/h

Filter capacity:0.5-1.2t/h |

17 | V202 | 清油箱

cleaning oil tank | QYX2.0 | 1 | 0 | 0 | 碳钢

Carbon steel |

18 | P202 | 齿轮泵

gear pump | KCB83.3 | 1 | 1.5 | 1.5 | 把油输送到油罐

The oil was convey the oil tank |

19 | X201 | 除尘沙克龙

De-dusting cyclone | XF40 | 1 | 0 | 0 | 碳钢,收集尘土和轻杂

Carbon steel, collect dust and light impurity |

20 | B201 | 闭风器

air-locked | BF5 | 1 | 0.55 | 0.55 | 带观察筒,封闭气体 With observing tube, sealed gas |

21 | F201 | 除尘风机

De-husting fan | 4-72NO4A | 1 | 3 | 3 | 带减震垫,调风门

With shock pad, air shutter |

22 | X202 | 去石沙克龙

Destoner cyclone | XF40 | 1 | 0 | 0 | 碳钢,收集尘土和轻杂 Carbon steel, collect dust and light impurity |

23 | F202 | 去石风机

Destoner fan | 4-72NO3.2A | 1 | 2.2 | 2.2 | 带减震垫,调风门

With shock pad, air shutter |

24 | B202 | 闭风器

air-lock | BF5 | 1 | 0.75 | 0.75 | 带观察筒,封闭气体 With observing tube, sealed gas |

25 | X203 | 沙克龙

Cyclone | XF40 | 1 |

|

| 碳钢,收集尘土和轻杂

Carbon steel, collect dust and light impurity |

26 | F203 | 风机

Fan | 4-72NO3.2A | 1 | 2.2 | 2.2 | 带减震垫,调风门 With shock pad, air shutter |

27 | B203 | 闭风器

Air lock | BF5 | 1 | 0.75 | 0.75 | 带观察筒,封闭气体

With observing tube, sealed gas |

28 | X204 | 沙克龙

Cyclone | XF40 | 1 | / | / | / |

29 | B204 | 闭风器

Air lock | BF10 | 1 | 1.1 | 1.1 | / |

30 | Z202 | 空压机

Air compressor | V-0.67/8-4KW | 1 | 4 | 4 | 压缩空气吹扫滤饼,提高出油率

the compressor air blow the cake to improve the oil yield |

31 | V203 | 压缩空气储气罐

Pressured air storage tank | KQG60 | 1 | 0 | 0 | / |

|

| 设备合计 |

|

|

| 148.1 |

|

|

| 电控

Power Distribution Control |

|

|

|

| MCC柜,正泰电器

MCC cabinet, CHNT |

|

| 安装材料

installation material |

|

|

|

| 管道、法兰、阀门

piping,valve and flange |

|

| 油漆保温

Painting ,Insulation |

|

|

|

| 出厂两道底漆两道面漆

Two primers and two top coats at the factory |

Number 2: Solvent Extraction workshop

I.Process description

iGeneral description

Solvent extarction equipment main function is extract oil out of prepared oil materials by using chemical solvent,normally N-hexane is widely used; After extract the oil out,will have DTDC and evaporation equipment to separate the solvent and oil&meal,;Then remove solvent from the solvent-laden meal, toast meal to control anti-nutritional factors, regulate the color, flavor and taste of the meal, reduce residual solvent in the meal and regulate the meal moisture, so as to guarantee the minimum solvent consumption and safe use of the meal and reduce moisture and temperature of meal to levels, which is appropriate for storage and transport; Condense and recover solvent gas for reusing.

ii.Main process and advantage

1. Features of extraction system description:

Adopt stainless steel fixed grid plate and increase the horizontal grid plates, which can prevent the strong miscella from flowing back to the blanking case, so as to ensure good extraction effect;

The rotocel extractor is driven by rack, with unique rotor of balanced design, low rotating speed, low power, smooth operation, no noise and quite low maintenance cost;

The feeding system can adjust the rotating speed of airlock and main engine according to the feeding quantity and maintain a certain material level, which is beneficial to the micro negative pressure inside the extractor and reduce the solvent leakage.

The advanced miscella circulation process is designed to reduce the fresh solvent inputs, reduce the residual oil in meal, improve the miscella concentration and save energy by reducing the evaporation capacity.

The high material layer of the extractor helps to form immersion extraction, reduce the meal quality in miscella, improve the quality of crude oil and reduce the evaporation system scaling.

Specially suitable for the extraction of various pre-pressed meals.

Solvent extractor

2. DTDC(Desolvent,toast,dryer and cooler for the meal):

1) DTDC adopts multi-layer structure, pre-dissolving, breathable layer, dissolving (setting high level material level) to adapt to meal dissolution, material layer and moisture easy to adjust.

2) Each layer using stainless steel automatic material pendulum door, the main dissolving layer according to the height of the material layer, automatic frequency conversion adjustment of the rotating valve speed, good solubility, reliable operation.

3) Main motor using domestic brand-name products, high-performance spindle, bearing processing, reduce transmission friction, improve equipment operating efficiency and life.

4) DTDC main reducer using brand-name high-strength hard tooth surface reducer, forced lubrication, life-long trouble-free operation. Low-end configuration is the medium tooth surface reducer, short life is generally about 3 years need to replace the reducer.

5) Passivation and destruction of anti-nutrient components such as urea enzyme and trypsin in meal to improve the utilization value of meal.

6) Controlling the degree of protein denaturation in meal and effectively improving the NSI index of meal.

7) The color, fragrance and granularity of the meal were well adjusted.

8) To better reduce the residual solubility in the meal, adjust the moisture content of the meal, so as to ensure the lowest solvent consumption in production and the safe use of meal.

DTDC

3. Miscella evaporation process

1

1

Micessla primary rotary liquid separation, two grade stainless steel filter , miscella oil impurities content very low, high quality crude oil.

2

The use of energy-saving device makes a second use of the waste steam from DTDC and steam injection pump,increase the condensate water temperature into above 50 ℃ in the water separate tank.

The use of oil-oil heat exchanger in the evaporation process of miscella makes full use of the residual heat of solvent extraction crude oil.

The use of heat exchangers in the paraffin recovery process will exchange high temperature paraffin lean oil and low temperature paraffin rich oil heat, saving energy.

Collect all the spent water and pump it back into the boiler room to save production water.

Application of large amount of unit temperature automatic control and pressure automatic control,not only makes the operation of the system stable, product quality is better, but also reduces the human error on the energy of a large amount wasting.

Miscella evaporation system

4. Solvent condensation & recovery process:

Solvent condensation system combines with evaporation system closely, and evaporative condenser and steam stripping condenser all work under negative pressure. Non-condensable gas enters the energy saver from the shell of the first evaporator. In energy saver, non-condensable gas exchanges heat with condensate from the evaporative condenser. Finally, the condensate temperature discharged from energy saver is increased, and the solvent separated from water goes to solvent holding tank. The high temperature makes it unnecessary to be reheated for the recycling, so as to save energy.

2.Non-condensable gas from energy saver enters desolventizing condenser, in which a great deal of gas is condensed, and the tail gas is discharged into the final condenser. The solvent gas from the extractor enters extraction condenser, and the non-condensable tail gas enters the final condenser. For the free gas in final condenser, diversion box, holding tank, underground solvent library and miscella tank, cool them with low-temperatured cold water to recycle most of solvent gas. The tail gas with little solvent goes to paraffin recovery process.

Solvent condensation & recovery process

5. Paraffin oil recovery process :

1.Tail gas first enters paraffin absorption tower, and then comes the counter-current absorption of paraffin and tail gas, which can reach the ideal state when the stainless steel packing has large surface area. The solvent content in discharged liquid paraffin (called rich oil) is not more than 5%, so as to ensure the maximum absorption rate

2.The paraffin rich oil is pumped into the heat exchanger to exchange heat with paraffin lean oil, and then goes to paraffin heater, and finally enters paraffin analysis tower. In the analysis tower, the steam-liquid heat exchange is conducted on the surface of stainless steel packing surface with direct steam and rich-oil paraffin, which can remove the solvent in the paraffin. This kind of paraffin, also called lean oil, exchanges heat with rich oil, and then is cooled to the ideal absorption temperature through the cooler. Next, it enters absorption tower for recycling. The gas mixture from the analysis tower enters energy saver, and the tail gas from the absorption tower is discharged from workshop with the fan.

3.In solvent recovery system, the solvent enters the holding tank through water tank, and the condensed waste water is discharged from water tank. If the tail gas contains certain solvent, cook it with the cooker to make it meet the emission requirements.

Paraffin oil recovery process

II. Equipment List:

10吨预榨饼浸出车间清单

10 tons per day pre-press cake solvent extraction equipment list |

序号 number | 名称

Name | 位号

Position Number | 型号

Model | 数量

Q.T.Y | 动力

Power

(KW) | 单项总动力

Total Power(KW) | 备注

Remarks |

1 | 存料箱

Storage box | Q-01 | YCL120*45 | 1 | 0 | 0 | 碳钢

Carbon steel |

2 | 1B刮板输送机

Scraper conveyor | Q-02 | MCQ12 | 1 | 2.2 | 2.2 | 防爆电机

Explosion-proof motors |

3 | 1封绞龙

Auger | Q-03 | YLS20*150 | 1 | 2.2 | 2.2 | 防爆电机

Explosion-proof motors |

4 | 平转浸出器

Extractor | Q-06 | JP200 | 1 | 0.75 | 0.75 | 变频调速,不锈钢栅板,防爆电机,转子驱动用外部电机减速机直联齿轮驱动外部大型圆锥齿轮传动,大齿轮采用铸钢材质,终身无故障运行;

Variable frequency speed regulation, stainless steel grid plate, explosion-proof motor, external motor for rotor drive, reducer directly connected gear drive external large bevel gear transmission, large gear is made of cast steel, and it can run without failure for life |

5 | 新鲜溶剂高位罐

Fresh solvent high tank | Q-05 | YS60*40 | 1 | 0 | 0 | / |

6 | 溶剂泵

Solvent pump | Q-07a-f | ALW25-110 | 6 | 0.55 | 3.3 | 防爆电机,耐溶剂机械密封

Explosion-proof motor, solvent resistant mechanical seal |

7 | 过滤器

Filter | Q-04 | YLJL30 | 1 | 0 | 0 | / |

8 | 浓混合油溶剂泵

Concentrated mixed oil solvent pump | Q-09 | ALW25-160 | 1 | 1.5 | 1.5 | 防爆电机,耐溶剂机械密封

Explosion-proof motor, solvent resistant mechanical seal |

9 | 2B刮板输送机

Scraper conveyor | Q-10 | MCQ12 | 1 | 2.2 | 2.2 | 防爆电机

Explosion-proof motors |

10 | 2封绞龙

Auger | Q-11 | YLS20*90 | 1 | 2.2 | 2.2 | 防爆电机

Explosion-proof motors |

11 | 捕集器

Catcher | Q-15 | YBJS50 | 1 | 0 | 0 | / |

12 | 蒸脱机

DTDC | Q-12 | DT110*4 | 1 | 5.5 | 5.5 | 压力容器,料摆轴不锈钢

Pressure vessel, material swing shaft stainless steel |

13 | 蒸汽加热器

Steam heater | Q-13 | RHZ2 | 1 | 0 | 0 | 压力容器

Pressure vessel |

14 | 3B刮板输送机

Scraper conveyor | Q-14 | MCQ12 | 1 | 2.2 | 2.2 | 防爆电机

Explosion-proof motors |

15 | 蒸汽加热器

Steam heater | Q-25 | RHZ2 | 1 | 0 | 0 | 压力容器

Pressure vessel |

16 | 分水罐

Water tank | Q-31 | LSX1.2 | 1 | 0 | 0 | / |

17 | 热水泵

Hot water pump | Q-32 | ALW25-160 | 1 | 1.5 | 1.5 | 防爆电机,机械密封

Explosion-proof motor, mechanical seal |

18 | 盐水罐

Brine tank | Q-16 | YSGY20 | 1 | 0 | 0 | 碳钢

Carbon steel |

19 | 溶剂预热器

Solvent preheater | Q-27 | RJRQ108 | 1 | 0 | 0 | 碳钢

Carbon steel |

20 | 分汽缸

Sub-cylinder | Q-26 | FQG0.8 | 1 | 0 | 0 | 压力容器 |

21 | 混合油罐

Mixed oil tank | Q-17 | YYGH80 | 1 | 0 | 0 | 碳钢

Carbon steel |

22 | 回渣泵

Slag Return Pump | Q-18 | ALW25-125 | 1 | 0.75 | 0.75 | 防爆电机,机械密封,开式叶轮

Explosion-proof motor, mechanical seal, open impeller |

23 | 第一长管蒸发器

First evaporation | Q-19 | RZF5 | 1 | 0 | 0 | 压力容器不锈钢换热管

Pressure vessel stainless steel heat exchange tube |

24 | 一蒸闪发箱

First evaporation flash tank | Q-49 | SZF9 | 1 | 0 | 0 | 碳钢

Carbon steel |

25 | 第二长管蒸发器

Second evaporation | Q-20 | RZF3.5 | 1 | 0 | 0 | 压力容器不锈钢换热管

Pressure vessel stainless steel heat exchange tube |

26 | 二蒸闪发箱

Second evaporation flash tank | Q-50 | SZF4 | 1 | 0 | 0 | 碳钢

Carbon steel |

27 | 层蝶式气体塔

Stripping tower | Q-21 | QDT325 | 1 | 0 | 0 | 压力容器不锈钢碟盘

Pressure vessel stainless steel disc |

28 | 毛油箱

Crude oil tank | Q-23 | YYGM70*80 | 1 | 0 | 0 | 碳钢

Carbon steel |

29 | 毛油泵

Crude oil pump | Q-24 | ALW25-125 | 1 | 0.75 | 0.75 | 防爆电机,耐溶剂机械密封

Explosion-proof motor, solvent resistant mechanical seal |

30 | 新鲜溶剂泵

Fresh solvent pump | Q-29 | ALW25-125 | 1 | 0.75 | 0.75 | 防爆电机,耐溶剂机械密封

Explosion-proof motor, solvent resistant mechanical seal |

31 | 溶剂周转库

Solvent turnover library | Q-28 | YZKR120 | 1 | 0 | 0 | 碳钢

Carbon steel |

32 | 分水箱

Water distribution tank | Q-30 | YSXF150*60*240 | 1 | 0 | 0 | 碳钢

Carbon steel |

33 | 浸出冷凝器

Extraction condenser | Q-36 | YLNL20 | 1 | 0 | 0 | 列管不锈钢

Column tube stainless steel |

34 | 蒸脱冷凝器

Desolventizer condenser | Q-37 | YLNL30 | 1 | 0 | 0 | 列管不锈钢

Column tube stainless steel |

35 | 空气平衡罐

Balance tank | Q-38 | PHG50 | 1 | 0 | 0 | 碳钢

Carbon steel |

36 | 最后冷凝器

Final condenser | Q-39 | YLNL20 | 1 | 0 | 0 | 列管不锈钢

Column tube stainless steel |

37 | 一蒸冷凝器

First evaporation condensor | Q-33 | YLNL30 | 1 | 0 | 0 | 列管不锈钢

Column tube stainless steel |

38 | 二蒸冷凝器

Second evaporation condensor | Q-34 | YLNL10 | 1 | 0 | 0 | 列管不锈钢

Column tube stainless steel |

39 | 汽提冷凝器

Stripping condenser | Q-35 | YLNL10 | 1 | 0 | 0 | 列管不锈钢

Column tube stainless steel |

40 | 尾气回收塔

Tail gas recovery tower | Q-40 | YXSY20 | 1 | 0 | 0 | 外壳碳钢,内部不锈钢填料

Shell carbon steel, internal stainless steel packing |

41 | 凉水塔

Cool Water Tower | Q-41 | GBNL3-30 | 1 | 2.2 | 2.2 | 碳钢框架,PVC填料

Carbon steel frame, PVC filler |

42 | 循环水泵

Circulating pump | Q-43ab | TPWY65-160 | 2 | 4 | 8 | 防爆电机,机械密封

Explosion-proof motor, mechanical seal |

43 | 室外溶剂罐

Outdoor solvent tank | Q-44 | RJG-20 | 1 | 0 | 0 | 碳钢

Carbon steel |

44 | 室外溶剂泵

Outdoor solvent pump | Q-45 | 50CYZ-A-32 | 1 | 3 | 3 | 防爆电机

Explosion-proof motors |

45 | 出粕刮板输送机

Meal scraper conveyor | Q-46 | MCQ12 | 1 | 2.2 | 2.2 | 防爆电机

Explosion-proof motors |

46 | 真空水浴罐

Vacuum water bath tank | Q-48 | SYG50 | 1 | 0 | 0 | 碳钢

Carbon steel |

47 | 真空泵

Vacuum pump | Q-47 | SZB-4 | 1 | 1.5 | 1.5 | 防爆电机

Explosion-proof motors |

48 | 设备 |

|

| 52 |

| 42.7 |

|

49 | 安装材料

Installation material |

|

|

|

|

| 管道、阀门、流管、垫片、法兰、螺栓、螺母等

Pipes, valves, flow pipes, gaskets, flanges, bolts, nuts, etc. |

50 | 油漆保温

Painting ,Insulation |

|

|

|

|

| 出厂两道底漆两道面漆Two primers and two top coats at the factory |

51 | 配电控制

Distribution control |

|

|

|

|

| GDD配电柜,桥架、电缆

GDD distribution cabinet, bridge, cable |

Number 3: Refining workshop

I Equipment List:

No. | Location | Name | Model | Q.Y.T | Unit Power (KW) | Total Power (KW) | Technical

parameters |

1 | P101 | 齿轮油泵 Gear oil pump | KCB83.3 | 2 | 0.75 | 1.5 | Stainless steel gear, cast steel shell |

2 | V101ab | 精炼锅 Refining pot | LYY150 | 2 | 0.75 | 1.5 | 0.75/1.5KW,within heating coil, Q235,µ=4mm |

3 | V103 | 热水碱水箱 Hot and alkali water tank | SX1.0 | 1 | 0 | 0 | Q235,µ=4mm |

4

| V102 | 磷酸罐 Phosphoric acid tank

| LSG40 | 1 | 0 | 0 | 304 Stainless steel |

5 | V104 | 溶碱配碱池 Soluble alkali and alkali pool | RJX100 | 1 | 0 | 0 | 304 Stainless steel |

6 | V302 | 真空捕集器 Vacuum catcher | FY1 | 1 | 0 | 0 | Q235,µ=4mm |

7 | P1000 | 水汽串联喷射泵 Water vapor pump in series | ZZSP160 | 1 | 0 | 0 | Stainless steel nozzle, cast steel shell |

8 | P1001 | 水泵 Water pump | IS80-65-160 | 1 | 7.5 | 7.5 | Stainless steel impeller cast steel shell

|

9 | V201 | 脱色锅 Bleaching pot | TSG150 | 1 | 0.75 | 0.75 | Mechanical stirring, direct steam nozzle, within heating coil, Q235,µ=4mm |

10 | V202 | 白土箱 Bleaching earth tank | BT0.4 | 1 | 0 | 0 | Q235,µ=4mm |

11 | P201 | 脱色泵 Bleaching pump | IY50-32-160 | 1 | 7.5 | 7.5 | Stainless steel impeller cast steel shell

|

12 | V203 | 叶片过滤机 Vibrate filter | MBL45 | 1 | 0 | 0 | Stainless steel filter cast steel shell

|

13 | V204 | 脱色油箱 Bleaching oil tank | 100*100 | 1 | 0 | 0 | Q235,µ=3mm |

14 | V205 | 油汽分离器 Oil steam separator | FY1 | 1 | 0 | 0 | Q235,µ=3mm |

15 | V206 | 水汽分离器 Water steam separator | FYQ50 | 1 | 0 | 0 | Q235,µ=4mm |

16 | P104 | 碱液泵 Liquid alkali pump | LY-100 | 1 | 0 | 0 | / |

17 | P1003 | 空压机 Air compressor | 2V-0.3/7 | 1 | 3 | 3 | Pressure vessel |

18 | V301 | 脱臭锅 Deodorization pot | TXG150 | 1 | 0 | 0 | 304 Stainless steel µ=4mm |

19 | V210 | 汽水分离器 Steam water separator | FLQ20 | 1 | 0 | 0 | Q235,µ=4mm |

20 | E312 | 冷凝器 Condenser | LNN15 | 1 | 0 | 0 | 304,µ=3mm |

21 | E311 | 蒸汽加热器 Steam heater | ZFQ80 0*2000 | 1 | 0 | 0 | Pressure vessel, Q235,µ=4mm |

22 | P301 | 脱臭泵 deodorization oil pump | IY65-50-200 | 1 | 3 | 3 | Stainless steel impeller cast steel shell |

23 | V313 | 过滤器 Filter | GLQ20 | 1 | 0 | 0 | Stainless steel 304 Filter area:5µ |

24 | V314 | 成品油箱 Product oil tank | CYX100 | 1 | 0 | 0 | Stainless steel 304 µ=3mm |

25 | P314 | 成品油泵 Product oil pump | ISW65-50-160 | 1 | 0 | 0 | Stainless steel impeller cast steel shell |

26 | R503 | 膨胀槽 Expand slot | BZC80*100 | 1 | 0 | 0 | Q235,µ=4mm |

27 | R502 | 储油罐 Storage oil tank | ZYG150*130 | 1 | 0 | 0 | Q235,µ=4mm |

28 | R501 | 导热油炉 Conduction oil boiler | ZRL20-MH | 1 | 0 | 0 | 200000Kcal/H |

29 | P501 | 导热油泵 Conduction oil pump | IY65-50-200 | 1 | 4 | 4 | Q235,µ=4mm |

SECTION-4: BUYER AND SELLER’S RESPONSIBILITY

一、Seller’s supply and service:

ØWhole set of equipment for production line;

ØEquipment setting layout,civil conditioning drawing;

ØMotor and power control system;

ØInstallation material;

ØInstallation and test-run;

ØDrawing of process description, equipment layout, foundation and hole, construction;

ØIsolation and painting for equipment;

ØStaff training and long-term technical service.

二、Buyer’s supply and service:

ØCrude and refining oil tanks outside the supply area;

ØBuildings, foundation, steel structure, platform, support facilities;

ØCleaning device inside the plant;

ØWater-sealed pool for vacuum pump;

ØHanging device;

ØGeneral power control and high voltage transformation;

ØEmergency power;

ØElectricity switch and cable outside the control panel;

ØLighting and lighting cable;

ØLightning conductor(except the extraction plant).

二、Engineering range taken by the buyer:

ØResponsible for the construction designing and construction;

ØResponsible for the installation for the whole set of equipment

ØResponsible for the freight and insurance outside China;

ØResponsible for all utility engineering, pipe works and tanks outside the plants;

ØPay for technical service (for installation guide, single machine test-run, test run, examining);

ØAdditional fee will be required to the construction drawing by the seller.

SECTION 9:3D VR design

1

1